Eco-engineering solutions to enhance marine biodiversity in Lyttelton Port

25 October 2023

Written by Gabe Ross

A multi-disciplinary approach led to a creative, low-tech innovation for coastal infrastructure.

One of the benefits of working in a multi-disciplinary firm like Boffa Miskell is the diversity of projects and unique challenges to address. Our long-standing collaboration with Lyttelton Port Company (LPC) focuses on boosting biodiversity in and around the port. This has included restoring native coastal planting, controlling weeds and pests, and most recently, developing “eco-engineering” solutions to enhance marine biodiversity on the port structures.

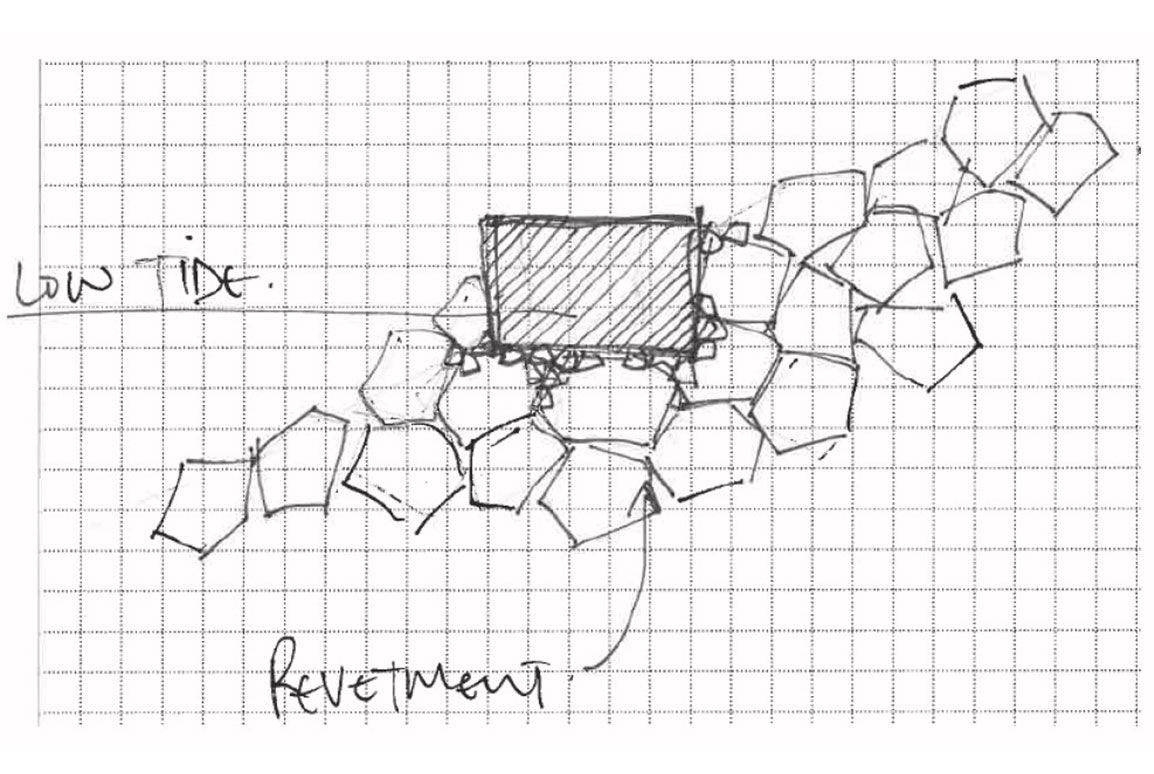

The eco-engineering work, led by marine ecologist Dr Tommaso Alestra, involved the development of a concept for artificial rock pools that could be placed within the port revetments. While there are a number of proprietary systems available, these typically have to be shipped from offshore, have limited water capacity and are very expensive. The client challenged us to find a low-cost way to test the concept using small batches of excess concrete from other LPC projects and locally sourced waste timber. The pools had to be robust enough to be precast and craned into location, durable enough to tolerate the harsh coastal conditions, and had to incorporate fine-scale surface texturing to provide a range of micro-habitats to marine organisms.

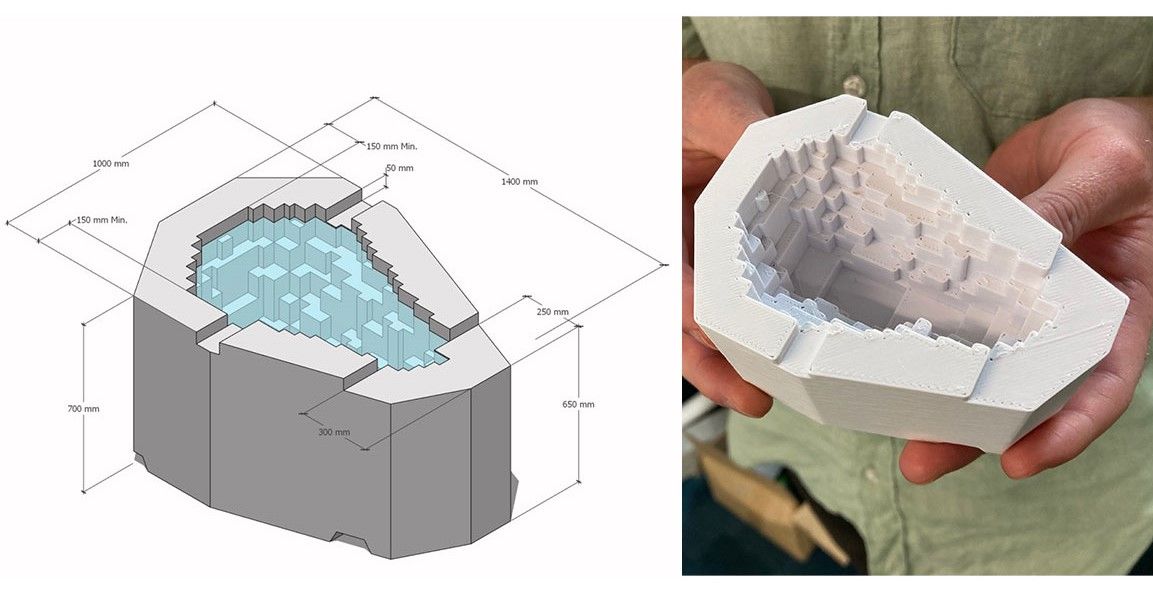

Tommaso pulled together the talents of the Boffa Miskell landscape architectural team, along with a technical specialist in industrial design and a local structural engineer from Kotahi Studio to develop a design for a modular artificial rock pool that would hold at least 100L of water and provide a diverse range of textures and forms to encourage colonisation by marine life. Several options were modelled and tested in 3D software, and a scale model of the preferred design was 3D printed.

The client used a friendly contractor to construct the formwork with a system of timber blocks of varying heights fixed to a central core to form the central pool. Achieving the desired level of fine-scale surface texturing while still being able to pull the formwork from the concrete was the biggest challenge.

A range of perishable elements was secured to the timber blocks to produce the surface texturing. These elements are meant to be left embedded in the surface of the concrete to form texture and voids as they decompose. We tested vegetables, seaweeds and other plant materials to identify the most effective and practical perishable elements.

The commitment to the project saw the LPC client and Boffa Miskell team members meet on site to prepare for the first pour in the midst of a southerly blast. A specially selected vivid green eco-friendly concrete release agent and a variety of locally sourced seaweed and plant material were stapled to the inner formwork leaving it looking appropriately like some strange organism from the deep. This was lifted in and secured into the outer formwork ready for the first pour.

The timber formwork was designed with the goal of lasting long enough to cast 4-5 prototypes to trial the concept. Adjustments were made after each pour to replace damaged components including swapping the initial plywood internal formwork with a steel box to improve durability. A layer of bubble wrap was also added to facilitate the release of the formwork from the concrete and provide additional surface complexity. Currently there are 3 units completed with hopefully a couple more to come.

The prototype rockpools will be placed within the port revetments before the next summer season and monitored to gauge how successful they are in increasing the diversity of marine life compared to the surrounding inhospitable revetment habitat. If successful, future developments may involve developing a more durable formwork system or potentially using a concrete 3d printer to upscale the pool fabrication.

This project is an excellent example of client, contractor, and ecology and design consultants finding a creative, low-tech solution to a challenge. We look forward to seeing the first inhabitants moving into the rock pools and to continuing to support LPC with their biodiversity and sustainability goals for the wider port.