From concept to production: the Nohonga Design Challenge

21 October 2020

With an early November installation day just two weeks away, we asked the Boffa Miskell finalists in the Nohonga Challenge for an update.

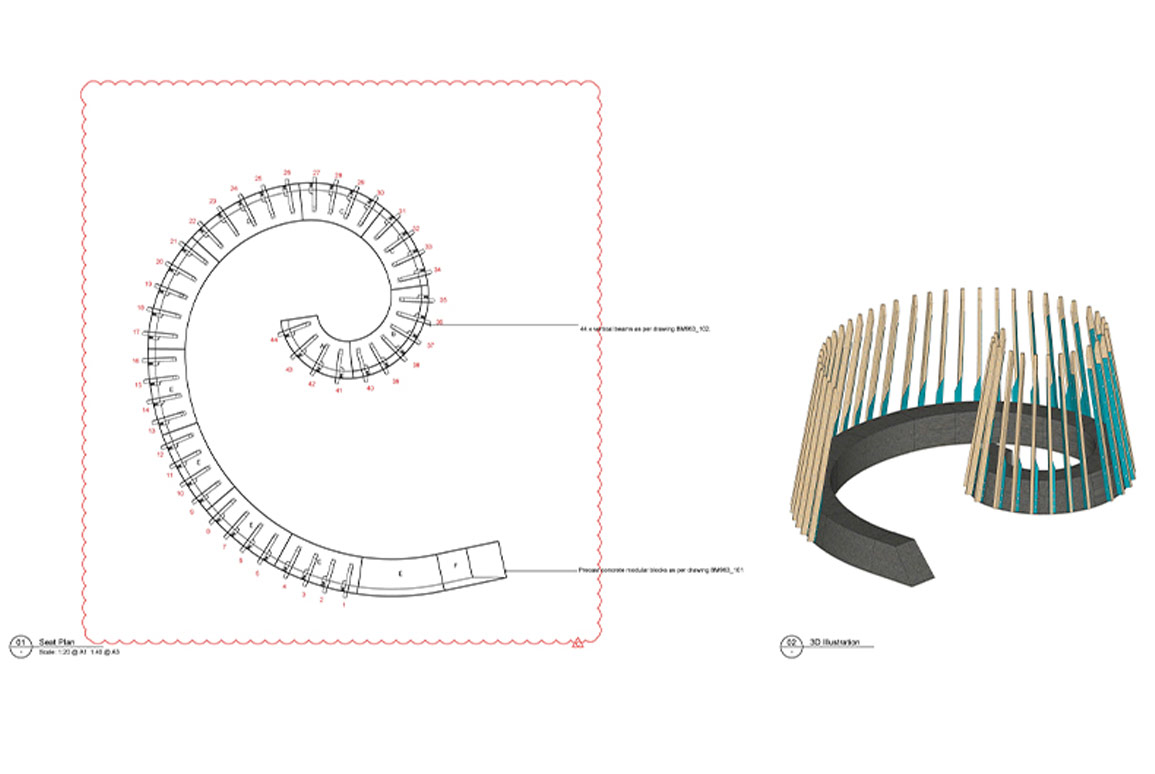

Topsy Steele and Anna Li make up Team Tauranga. Their design, Bioluminescence, incorporates design elements reflecting the coastal landscape and the shape of shells found there.

Team Tenax, based in Auckland, comprises Katherine Eastman, Alex Smith and Erin Diao. They collaborated with William Hatton on “Whiria” which references the weaving of Harekeke and its resonance in the weaving together of people.

After the finalist announcement, Team Tenax began by exploring the cost and feasibility of constructing the bench with several manufacturers. As part of that process, they were gifted a small model by Mobile Sheetmetals of Fielding, which the team plans to paint up and display in the Auckland office.

While finalsing their design, Team Tauranga made a few slight changes to make the design more builder-friendly. The vertical elements have been altered to minimise the risk of timber warp and increase stability. These changes allow the team to reduce the length of bolts required and add a little cost saving.

Additionally, the sweeping ramp which continued into the seat has been reduced to one exposed section and is a much steeper grade than the original design. This also enables easier construction, as the team won’t have issues with attaching the vertical elements to the concrete base.

Streetscape has come on board to assist both teams; and, for Team Tauranga, Streetscape has brought in Jagas, who have sponsored production of the concrete base.

Topsy says, “This was a huge win for us, and in the beginning figuring out how we were going to get the base right was a hurdle. We’re hopeful that the mould and pour will go smoothly, thanks to their help.”

Streetscape approved the shop drawings for Team Tenax, and Katherine says, “The design has not changed greatly since the initial concept, however some small details have been revised. These include adding a larger bend/radius to the corners of the folds to account for the brake press, and the addition of an angular foot at one end of the bench to better support it.”

The biggest challenge for Team Tenax has been selecting the right steel thickness. Too thin and the bench will be too light and easily moved, flipped or stolen. Too thick and the bench will be too heavy to place and move. The best option was 6mm, which will make the benches 130 kg each.

Team Tauranga have a more complicated design, and the heavy concrete base has created some challenges. Topsy says, “We had a bit of a hiccup with needing to include pallet jack sections for onsite instalment. The other major challenge has been figuring out how to cut the base into sections and consequently how the vertical fixings line up with the different modules (which all have a varying radius) without overlapping with cut lines.

“We addressed the section cuts and radius changes through using the golden ratio while also allowing for a 10mm gap between sections, with a chamfer so there is an allowance for slight changes/ masking on site.”

“We have been fortunate enough that both Jagas and Streetscape are heavily invested in the project (and providing their services free of cost) and share our vision of seeing this project through. Without them this project would not be possible.”

With production moving forward, both teams are thinking about installation at Britomart, Brick Bay, and beyond.

Katherine says her team has would like to install the seats in a courtyard or in the Westpac/EY Building atrium where passing commuters and shoppers can enjoy them.

Team Tauranga are pursuing the opportunity to eventually have the Nohonga brought back down to the Bay of Plenty to be installed locally for a period of time.